Inmotive's IngearFRD Brings Breakthrough Efficiency to Single-Speed Transmissions

Revolutionizing EV Drivetrains, One at a Time.

Inmotive, known for its innovative two-speed Ingear transmission, has just validated a major breakthrough that could reshape the electric vehicle (EV) drivetrain landscape. The company’s patented floating-sprocket and tensioned chain drive architecture—originally developed for multi-speed applications—has now demonstrated transformative benefits when applied to single-speed (fixed-ratio) EV drives, which represent the vast majority of passenger-vehicle EV transmissions today.

Early testing reveals that this architecture delivers higher efficiency, lower noise, and dramatically improved durability—all in a simpler, more compact, and cost-competitive package. This positions Inmotive’s Ingear FRD (Fixed-Ratio Drive) as a powerful new standard for EV drivetrains, with massive implications for adoption, scalability, and long-term industry impact.

A Simple Concept with Big Payoffs

The floating sprocket segment was initially adopted for the novel Ingear shifting method, and tolerances and compliance were optimized for manufacturing, noise and efficiency. During Inmotive’s testing of the sprocket -- without any shifting— the team discovered something surprising: the floating sprocket on its own provides significant mechanical benefits, even in non-shifting applications.

Key performance advantages include:

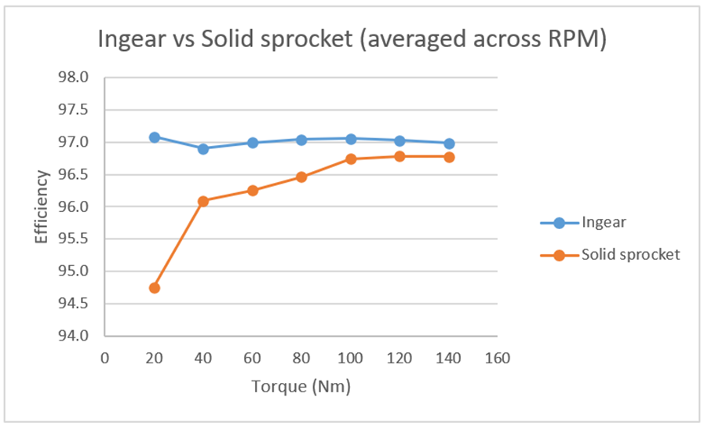

1–2% efficiency improvement across the torque spectrum

Load distribution across a greater number of sprocket teeth and chain teeth, reducing localized stress

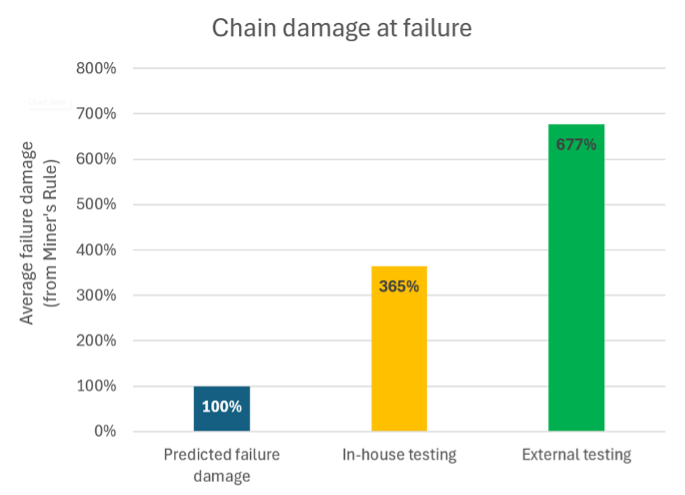

6× increase in durability compared to traditional solid sprocket

Audible reduction in noise

The compliant nature of the sprocket and chain system reduces stress concentrations, enabling narrower and lighter chains, or smaller diameter sprockets — cutting mass and cost without compromising lifespan.

Technical Highlights

Up to 2% higher transmission efficiency compared to conventional helical gear or solid sprocket drives.

600%+ increase in chain life due to more even load sharing.

Other Technical Highlights:

Lower NVH (Noise, Vibration, Harshness) thanks to smoother chain engagement and reduced vibration—IngearFRD has shown a 50% reduction in vibration and quieter operation.

The improved load-sharing means narrower chains (e.g., switching from 1.5” to 1.0” chain) can be used without sacrificing strength—cutting weight and cost.

Segmented sprockets can be manufactured using powdered-metal (PM) near-net-shape methods, reducing machining steps and further lowering costs at scale.

From Niche to Mainstream – Sprockets are Everywhere

Until now, Inmotive’s focus was on its two-speed Ingear system—offering step-function gains in efficiency and performance. While impactful, multi-speed EV gearboxes are still relatively niche in the market. In contrast, fixed-ratio (single-speed) drives dominate today's EV landscape.

By applying its chain drive architecture to single-speed applications, Inmotive unlocks a much larger market:

Mainstream EV EDUs (Electric Drive Units)

Transfer cases in AWD platforms

ICE transmissions with chain-driven elements

Heavy-duty and off-road applications where durability is paramount

IngearFRD is not just for EVs—the same benefits extend to hybrids, commercial vehicles, and industrial machinery, opening doors to high-duty cycles and cost-sensitive applications.

Physics Meets Economics

Inmotive's design leverages basic physics to unlock superior economics:

Cost parity is already in reach. Internal costing shows that IngearFRD is competitive with traditional helical gear sets right now. Over time, the simplified manufacturing and lower material usage will only widen the cost advantage.

Strategic Flexibility & Commercial Readiness

With IP filings underway and NDA-based briefings held with major Tier-1s and transmission suppliers, Inmotive is already engaging global industry leaders. The company sees multiple viable pathways to market:

Licensing to Tier-1 drivetrain suppliers

Direct component supply in collaboration with chain manufacturers

Retrofit opportunities for existing platforms

IngearFRD presents lower technical and commercial risk—an easy on-ramp to two-speed upgrades in the future.

What's Unchanged: The Two-Speed Vision

While IngearFRD opens up the fixed-ratio space, the original two-speed Ingear transmission remains the cornerstone of Inmotive’s product roadmap. The two-speed system still provides the largest range and performance gains for EVs, and IngearFRD now serves as a low-risk, high-value entry point for OEMs to begin adopting the broader Ingear architecture.

Conclusion: A Momentous Expansion for Inmotive

Inmotive’s IngearFRD represents a watershed moment for drivetrain technology. By proving that their unique floating-sprocket chain drive can deliver real-world benefits in mainstream single-speed EV applications, Inmotive has vastly expanded its addressable market.

What was once a high-efficiency niche solution is now positioned to redefine the standard for EV transmissions, offering:

Higher efficiency

Lower cost

Longer life

Easier packaging

Simpler manufacturing

IngearFRD: A smarter drivetrain architecture for the entire mobility sector.

About Inmotive Inc.

Inmotive is a pioneering developer of ultra-efficient multi-speed powertrains for electric vehicles. The company’s flagship product, the Ingear™ transmission, delivers superior efficiency and performance for a wide range of EV applications. Committed to advancing sustainable mobility, Inmotive partners with leading manufacturers to redefine what’s possible in electric and alternative energy transportation.