A New Era for EVs Demands a New Kind of Transmission

Ingear unlocks greater range, lower cost, and new possibilities for EVs.

Ingear accelerates the inevitable shift to electric vehicles.

Built for the EV Future

For decades, transmissions had been an unquestioned part of automotive design — until electric vehicles came along. With their instant torque and simplified drivetrains, EVs seem to operate well without the multispeed transmissions from the Internal Combustion Engine (ICE) age. However, look back at the early days of the automobile and the development of the first transmissions and you’ll see a landscape that mirrors where EVs are today. Read More

We Make Every EV

Drive Farther, Faster, and More Cost-Effectively

More consumers will choose EVs when they are more affordable, but still offer great performance and comparable range. Ingear enables more efficient powertrains that significantly reduce puchase and operating costs for the next generation of EVs.

Unlock New Performance Standards with

Smarter Systems Engineering

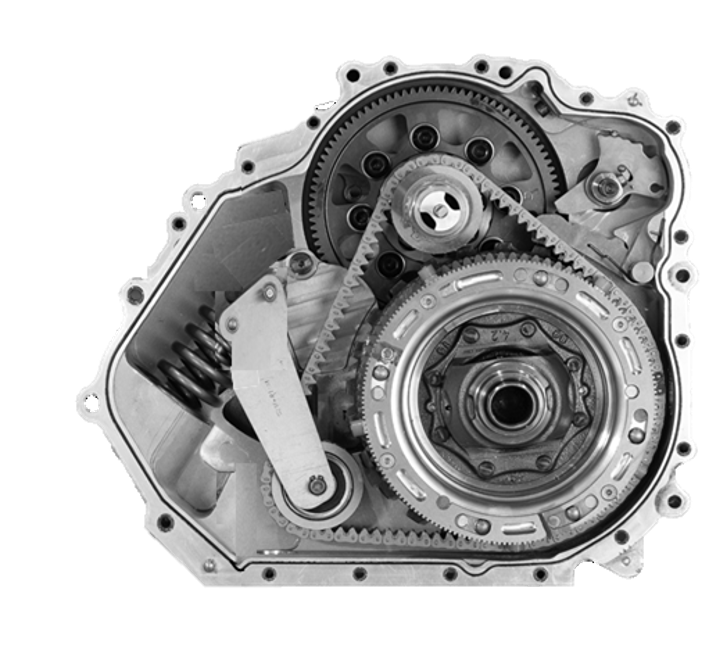

Ingear pairs a two-speed architecture with a chain-drive secondary reduction to boost launch torque, widen highway efficiency, and cut drivetrain noise. Multi-tooth load sharing and roller bearings slash friction, while a compliance-rich tensioner eliminates clutches, hydraulics, and ultra-tight machining—raising performance and lowering emissions in one move.

Ingear. Designed for EVs Engineered for Advantage

Chain-Drive Efficiency

A silent roller chain spreads torque across many teeth at once, cutting peak contact stress, frictional losses, and gear-whine all in one stroke. Rolling engagement removes axial thrust loads, so low-drag ball bearings replace heavy tapered rollers. The result: lower NVH, higher durability, and measurable energy savings between the motor and the wheels—benefits proven in everything from the Chevrolet Volt’s silent chain to Ingear’s own dynamometer runs.

Factory-Friendly

A tensioner helps absorb normal tolerance stack-ups, letting housings move from costly precision machining to efficient die-cast or powdered-metal processes. Looser center-distance targets mean fewer scrap parts, simpler fixturing, and faster line rates. Ratio tweaks often need nothing more than an off-the-shelf sprocket swap, avoiding case re-validation and re-tooling. Fewer tight-tolerance parts, fewer QA gates, lower cost per unit.

Seamless Shifting

Segment-shaped sprockets index only during natural zero-load windows, so no clutch packs, synchronizers, or high-pressure hydraulics are required. Geometry, not software, governs the shift—keeping control logic lean and shift repeatability high. With fewer moving parts and no wet friction elements, drivers gain significant performance with the same seamless torque from a single speed EV.

Performance Without Compromise

$1000+

System Cost Savings

Better efficiency allows for less battery and a simpler, smaller motor, resulting in an EV that is over $1,000 less expensive to produce, purchase and operate. An Ingear may cost the OEM as little as $150, while saving more than $1,000+ of battery, inverter and motor costs.

8–18%

Greater Range

Ingear-enabled EVs have longer range. The reduction in energy required to move the vehicle means that it can travel further with the same battery capacity.

+15%

Increased Acceleration and Top Speed

Single-speed transmissions are a compromise between efficiency and performance. With two gears, an Ingear powertrain can maximize for both city and highway use. Acceleration and top speed can be improved by over 15%.

More Miles. Fewer Rare Earth Minerals

SMALLER FOOTPRINT

An Ingear-enabled car requires less battery and can use a smaller, simpler motor. This reduces upstream demand for mining rare earths and expensive materials.

SCALE YOUR PLATFORM LINEUP

Once you add Ingear to your product portfoio, integrate in vehicles with motor power from 10kW through 300kW by simply increasing the chain width.

OEM-Validated. Road-Ready.

Aptera Motors, a leader in solar electric vehicle (sEV) technology, has announced a new strategic partnership with Inmotive Inc. to explore opportunities for increased efficiency and sustainability in solar-powered transportation. The companies are working together to integrate Inmotive’s Ingear™ two-speed transmission into Aptera’s future vehicles.

Learn More

Inmotive has signed a joint development agreement with Suzuki to develop an Ingear 2-speed EV transmission for a future Suzuki electric vehicle.

99% Peak Efficiency

Inmotive has received confirmation from a major global OEM that its Ingear two-speed EV transmission is the world’s most efficient two-speed transmission for electric vehicles.

Precision where it counts, clearance everywhere else.